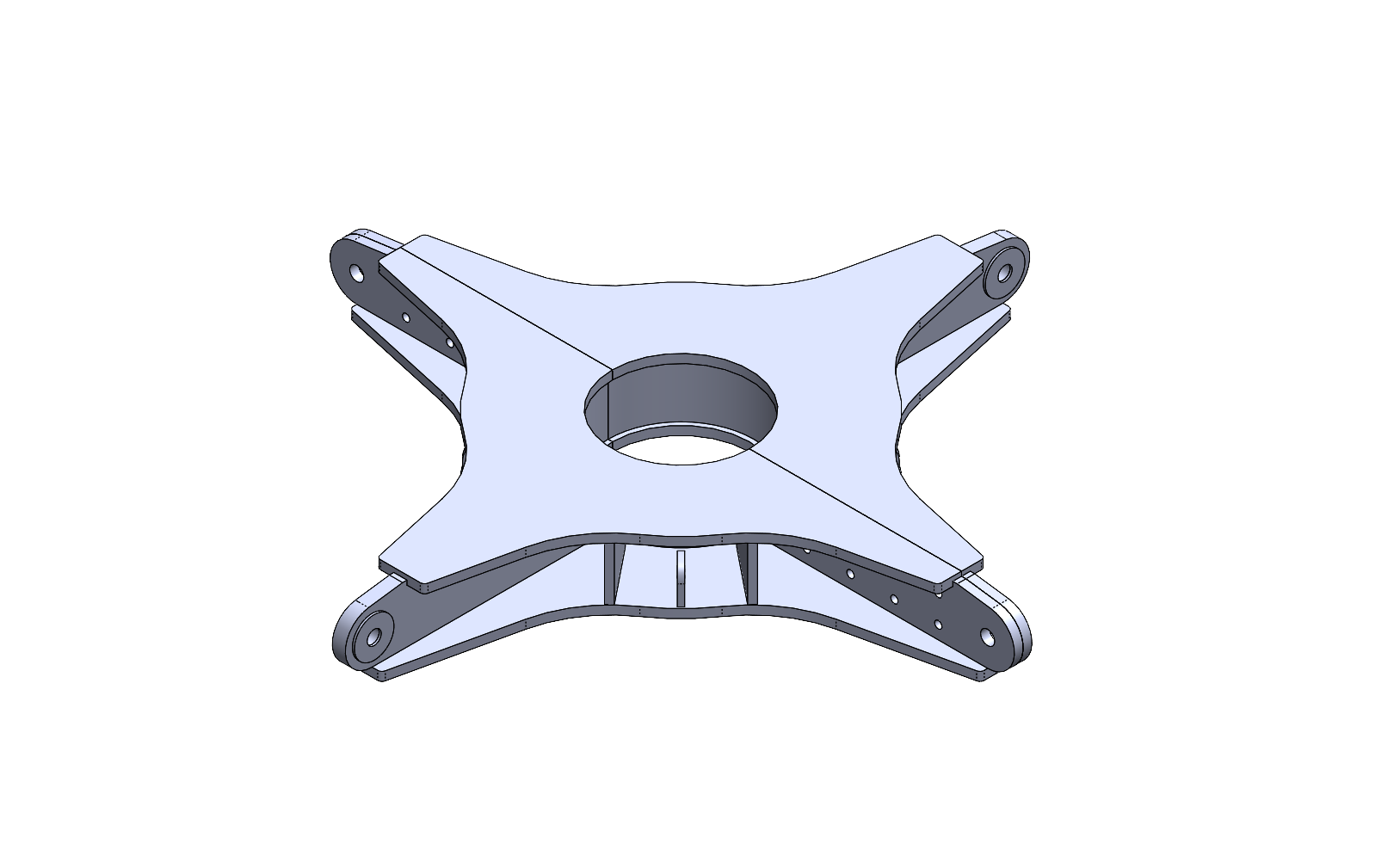

BOP Lifting Frame Design

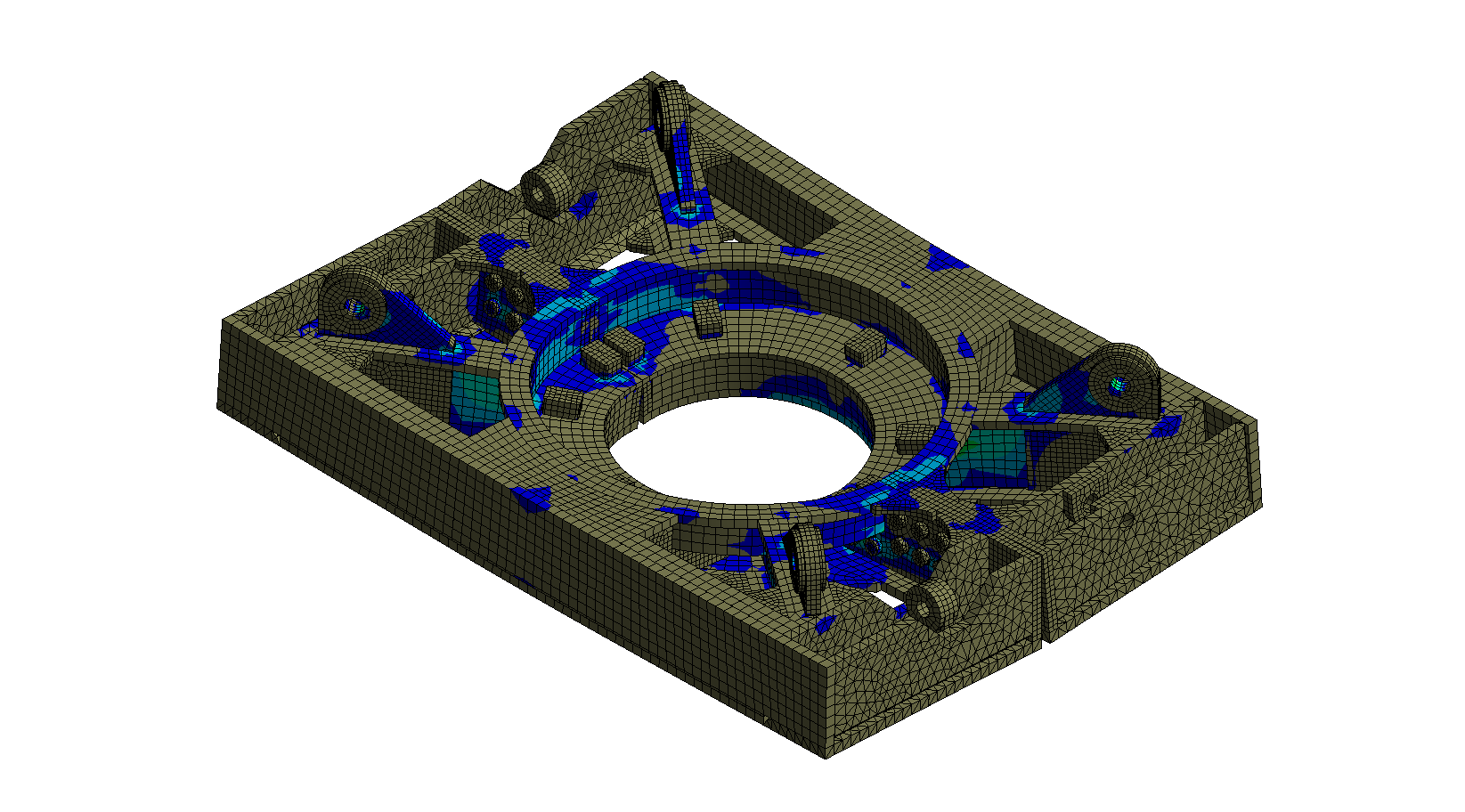

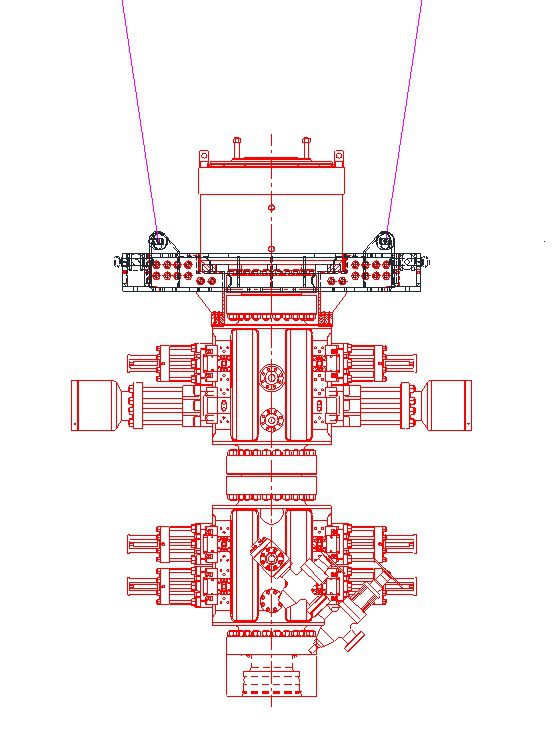

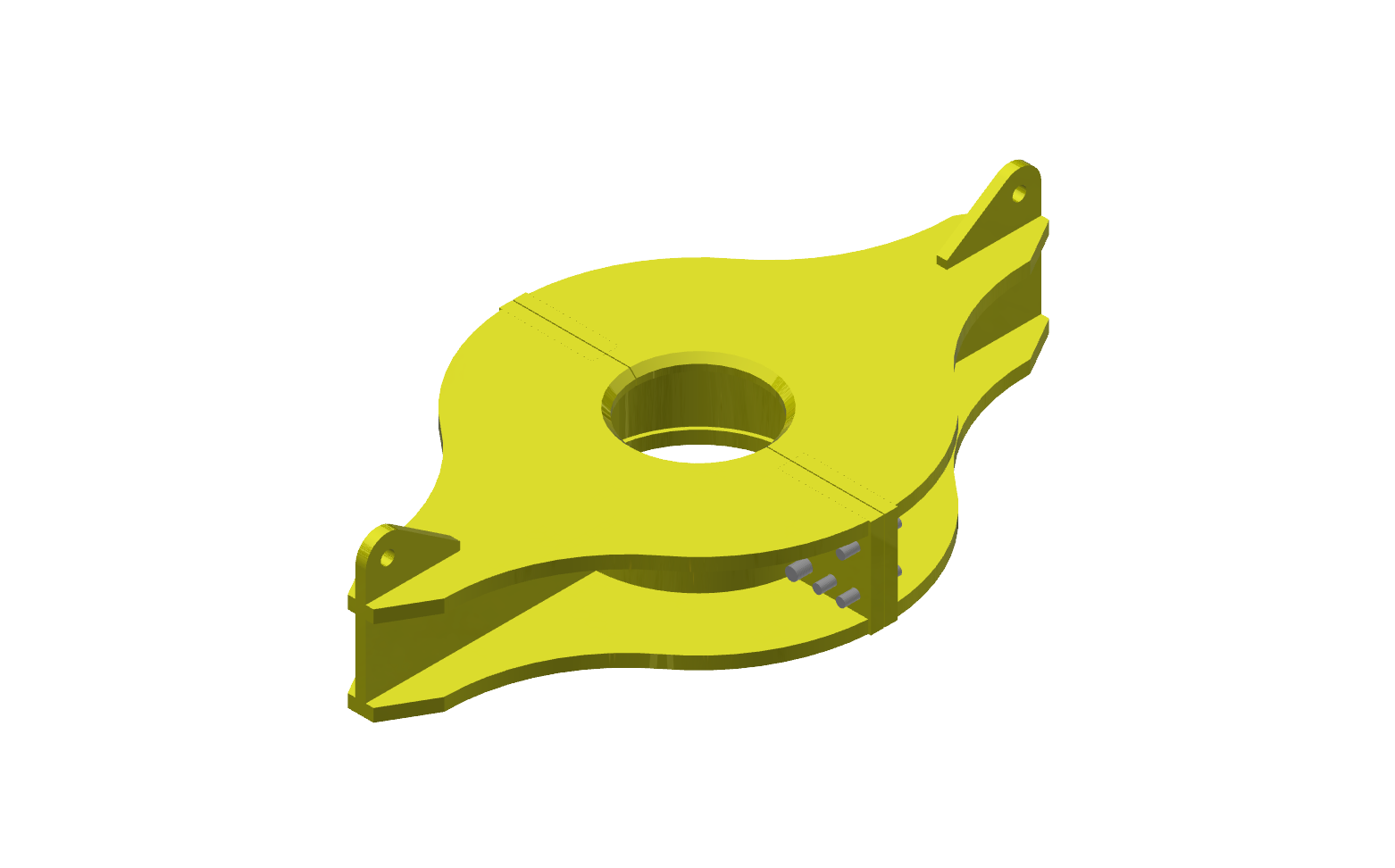

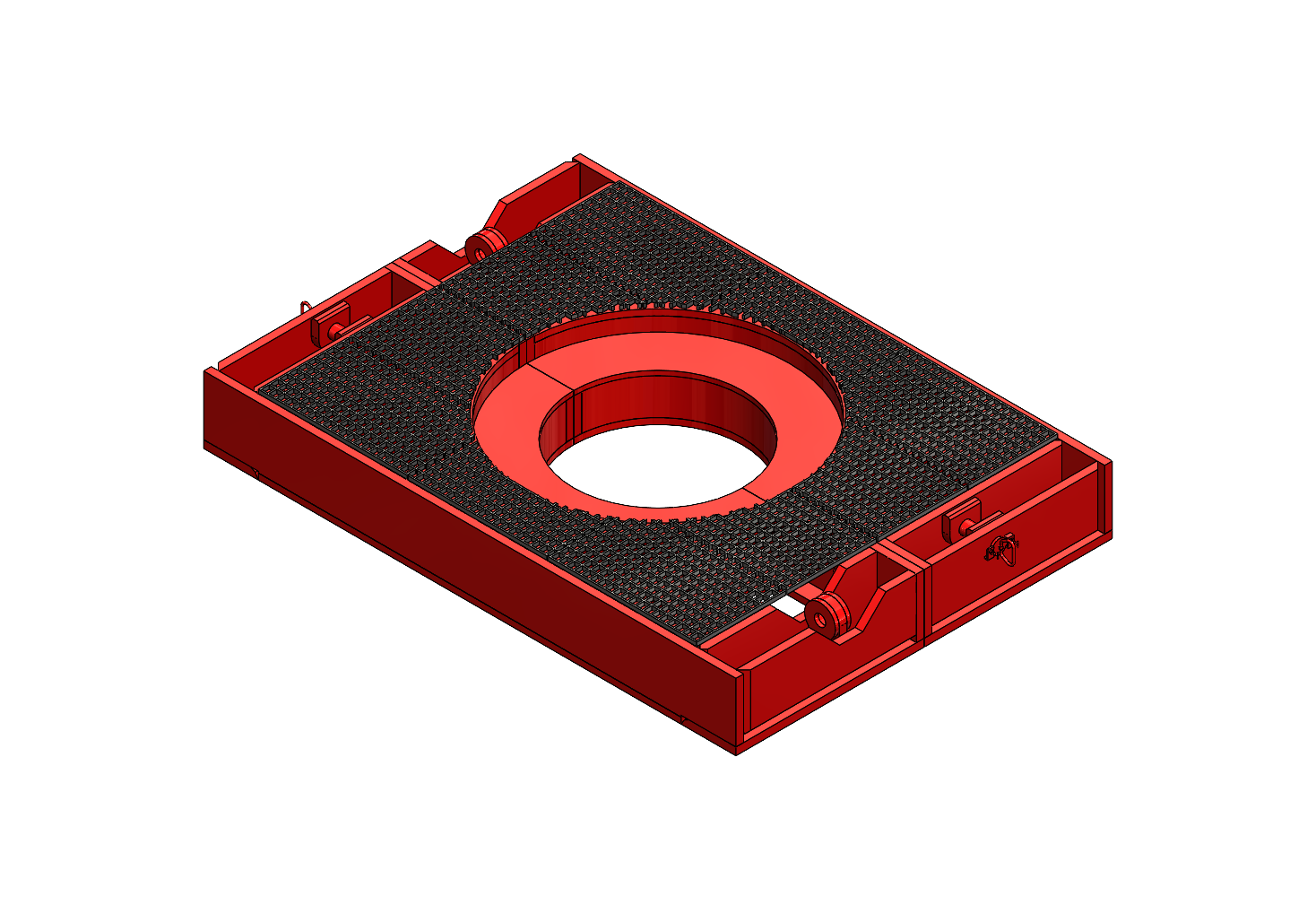

BOP (Blowout Preventer) lifting frame is one of the lifting appliances used to shift BOP stacks by chain hoist on the rig. Sometimes, drill operator modified the BOP lifting frame to add additional lifting padeye and secure with annular, the BOP elements are connected to the drilling conductor pipe and secured by the tensioning line. In fact, the full weight of whole stack of BOP elements and drilling conductor are supported by Conductor Tensioning Unit (CTU) system in this situation.

The BOP lifting frame design normally is secured with annular. The dimension of the lifting frame governed by the size of the annular. The size and outline of the annular is critical to geometry of the BOP lifting frame design. The common sizes of the annular are 7-1/16”, 9”, 11”, 13-5/8”, 16-3/4”, 18-3/4”, 21-1/4” and each size has different pressures from 3K, 5K, 10K, 15K, 20K and so on.

The strength capacity of the BOP lifting frame is calculated and analysed can be referred to ABS, API or DNVGL rules requirement. Such as:

- ABS guide for the Classification of Drilling System

- ABS guide for certification of Lifting Appliances

- API Specification 7K – Drilling and Well Servicing Equipment

- DNVGL-OS-E101 Drilling facilities

- DNVGL-ST-0377 Standard for shipboard lifting appliances

- DNVGL-ST-0378 Standard for offshore and platform lifting appliances

Comments

2 CommentsDear Sir, I need a quote for a BOP lifting frame, just let me know the technical information you need to design and quote us.

Regards

Hi Ramon Antonio,

For the quotation stage, you might need to provide the rate of the BOP lifting frame, operation temperature, and dimensions of the Annular and RAM. Whether a third party is required for calculation verification. such as DNV, ABS, API, BV or Lloyd.